We are all about solutions.

Historically, metal curb companies take the component approach – allowing the customer to be responsible for determining the correct curb size. This transfers responsibility to the builder, releasing the curb company from all responsibility. Curb support is then left to the contractor, accessories may or may not be included, and installation details are left to others.

The components approach creates problems. We’re here to create simple solutions.

Whether your issues are related to new construction or you have issues with a pre-existing structure, RCS offers the solution to meet your needs. Some of the most common problems engineers and builders contend with when planning and constructing buildings include thermal movement, panel elevation, full perimeter support and negative pressure. Learn how RCS can expertly solve these issues with the TRAC Rail System.

Thermal Movement

Most standing seam roof systems are designed to travel up to 1-1/4” in both directions with thermal expansion and contraction. If the roof is moving, so must the roof curb. Panel lock down is the primary cause of most roof leaks.

How the TRAC Rail can help

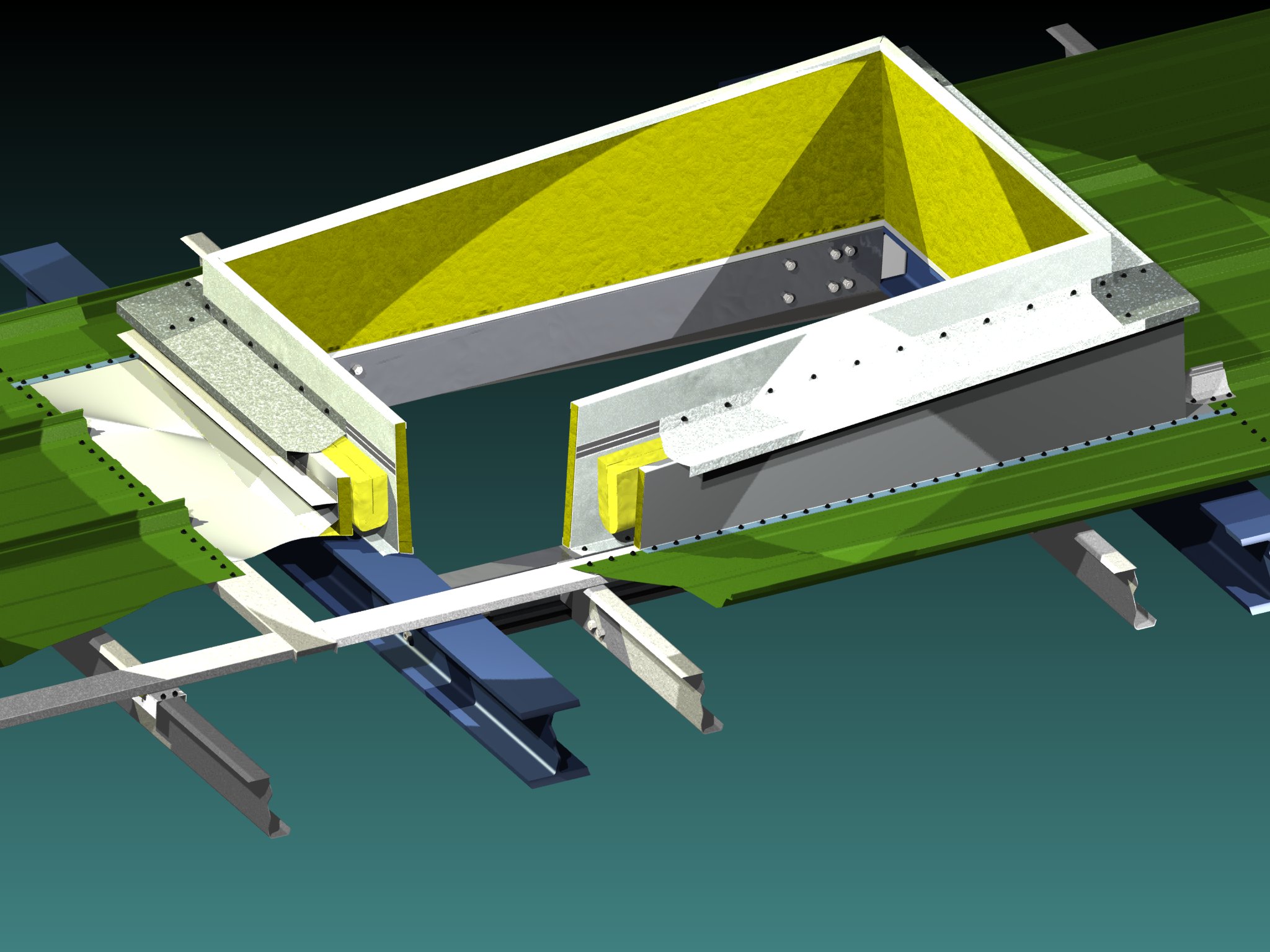

The patented TRAC Rail Curb Support System is pre-centered and shipped assembled to allow for up to 1-1/4” movement in both directions. This is accomplished without any field assembly or adjustments by the erector.

Panel Elevation

Most standing seam roofs are supported by clips that raise the roof panel above the purlin or bar joist, typically 3/8”, 1”, or up to 1-3/8”. To reduce ponding at the front of the roof curb, the roof curb must be elevated to the same plane as the roof panel.

How the TRAC Rail can help

The TRAC Rail Curb Support System is factory customized per job. A simple form is completed with the order which gives us the details we need for custom adjustment.

Full Perimeter Support

Ponding also occurs when there is no cross support at the front and rear curb flange. Without structural cross support at these critical areas, deflection will occur whenever someone stands near the curb to install the roof top equipment.

How the TRAC Rail can help

The Trac Rail system is shipped with the two cross channels pre-notched to match the roof curb’s interior dimension. The structural purlin span channels align with the roof curb. Roof Curb System’s welded Uni-Cricket aids in structural support. With no field notching required, erector labor is reduced.

Negative Pressure

Negative pressure is always a consideration with all roof designs. It can affect the integrity of roof penetrations such as skylights, smoke vents, exhaust fans and other relatively light weight equipment. Roof curbs can be slightly lifted or tilted by negative pressure, causing the sealant between the curb flange and the roof panel connection to be disturbed. When this seal is broken, the opportunity for leaks increases greatly.

How the TRAC Rail can help

The patented TRAC Rail Curb Support System is the only pre-assembled system that allows for full thermal movement while resisting negative pressure.

Mechanical Contractors Supplying and Installing Curbs

Mechanical Contractors should not be asked to supply or install roof curbs for metal roofs. All roof curbs should be supplied by the general contractor or building manufacturer and installed by an experienced erector. As a rule, the mechanical contractor is not familiar with metal roof systems and is not responsible for any leaks. There are many cases where conventional HVAC roof curbs have been installed on metal roofs. This results in ongoing maintenance issues for the general contractor.

How the TRAC Rail can help

Just fax the HVAC model number to us. We have a vast HVAC library and will coordinate the HVAC units with the metal roof system.

A good roof penetration requires more than supplying just a roof curb. Curbs as a component are widely available, but they are just that, “a component,” not a system…

Our TRAC Rail Roof Penetration System is the only system supplied by a Roof Curb Company designed to address the dynamics associated with standing seam roof systems and erector installation. When the erector or installer is on the roof, the last thing he needs to do is stop the job and field notch angles to frame a roof curb, or go look for sealants or fasteners. We can help you get the job done right the first time, fast.

About Our Service

Because RCS has experience in both the metal building and the HVAC industries we can identify and perfect the critical details. We coordinate the mechanical contractor's HVAC equipment details with the metal building's roof and framing layout conditions in order to guarantee a seamless fit. This makes RCS stand out from our competition.

At RCS we never ask our customers to give us a curb size for an order.

Instead, give us the HVAC unit model number and we’ll do the rest to ensure the curb will fit the roof top unit. We also recommend the best unit orientation to distribute unit loadings and allow supply and return to work with purlin or bar-joist spacing. Our service will save you time and money to keep you moving forward on the job, faster.

What Makes RCS Unique?

- Smart services. Exclusive HVAC coordination.

- Innovation. A System Solution approach to an industry full of component problems.

- Training. Sales Coordinators are cross-trained in Pre-Engineered and HVAC and are AUTO-Cad proficient.

- Superior advisement. We coordinate HVAC duct drops to joist lay-out and recommend the optimal orientation.

- Development. We actively develop improved installation methods working with erectors and service reps.

- The details. Installation details and shop drawings are shipped with all jobs.